Products

- Product line dedicated to general medical devices & instrumentation:

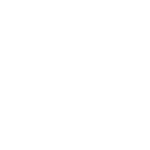

- Medical devices (class I and IIa) for minimally invasive general or ophtalmic surgery and dentistry, high precision cutting, perforing or grasping instruments & tools.

- Dedicated to our 3D microthermomoulding process

- Submillimetric parts dimensions

- Precision +/- 3µm

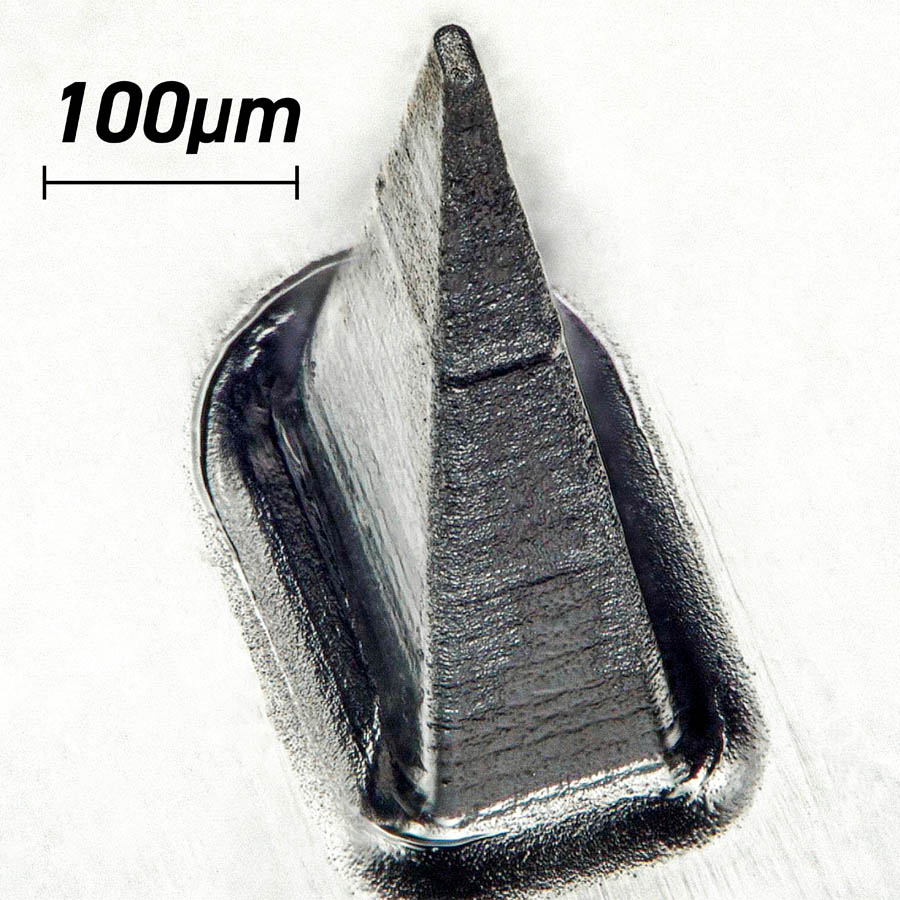

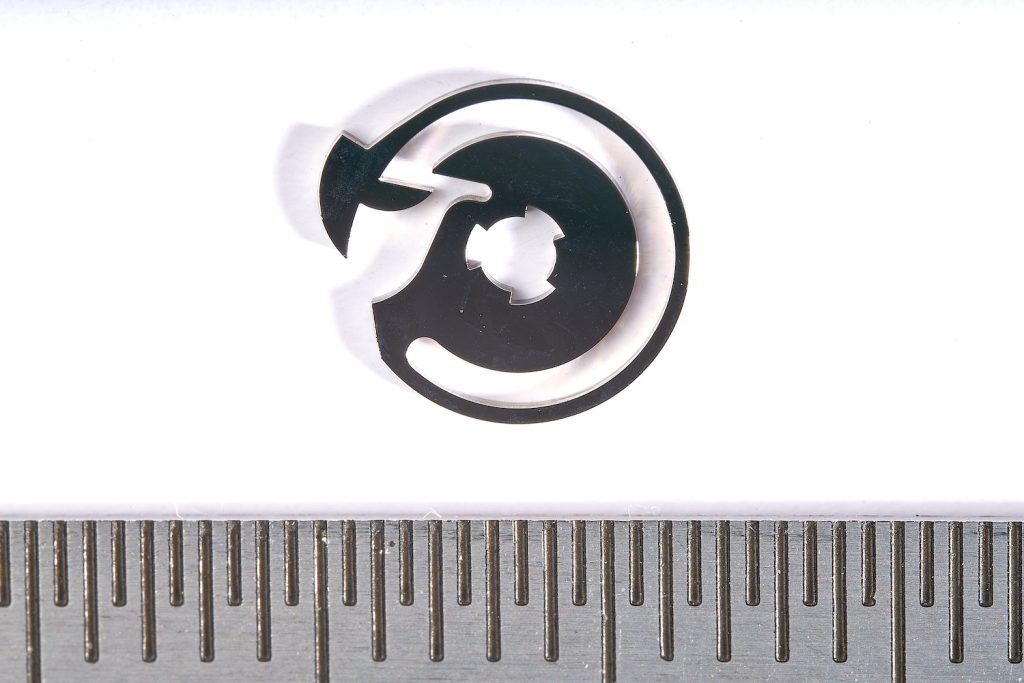

- Product line dedicated to watchmaking movement & micromechanisms performance: flexible parts, movement parts, gears, microsprings.

- Miniaturized and extreme-resistance parts.

- Reduced overall dimensions.

- Increased durability

- Dedicated to our 2D microthermomoulding process

- Product line also adapted for cutting post-processing steps such as LASER cutting or EDM for the most complex parts.

- Millimetric parts

- Precision +/-3µm

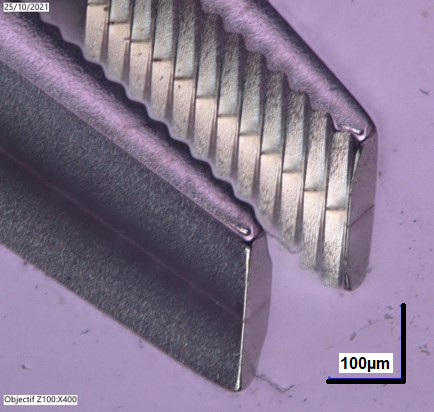

- Product line dedicated to highly stressed parts of medical devices such as dental & chirurgical implants: Implantable devices for dentistry, orthopedics, highly mechanically stressed instrumentation, motorized instrument components.

- Smaller implants & more durable devices

- One-Step 3D geometries of complex shapes and textures

- Millimetric to centimetric parts

- Precision +/-5µm

- Product line dedicated to Precious or not precious hallmarking parts for jewellery or watchmaking parts: watchcases, rings, leather-goods clasps, earrings, luggage parts.

- Lighter and more durable decorative parts

- High corrosion and scratch resistance for a lifetime jewellery

- A dedicated process particularly efficient in both energy and resources to safeguard up to 80% of the raw material

- Centimetric parts

- Precision +/- 5µm

Market fields and Applications

Watchmaking industry, luxury, medical, aeronautics, defense & space: Our Vulkalloys are known for their advantages reached from the manufacturing process as well as for their outstanding properties: mechanical strength, elasticity, tribological properties, thermal insulation, biocompatibility, etc.

Vulkalloys® are therefore perfectly suited for the miniaturization of mechanical systems and the production of miniature components with optimized shapes.

The Vulkalloys® range meets the needs identified during the design of miniature parts such as power transmission parts, springs, watch components, parts requiring a high level of finishing, but also those related to the requirements of medical devices, for surgical instrumentation or implantology.